Semi-Automatic NC Circular Saw

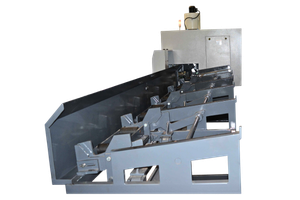

Flexible Operation with Hydraulic Precision

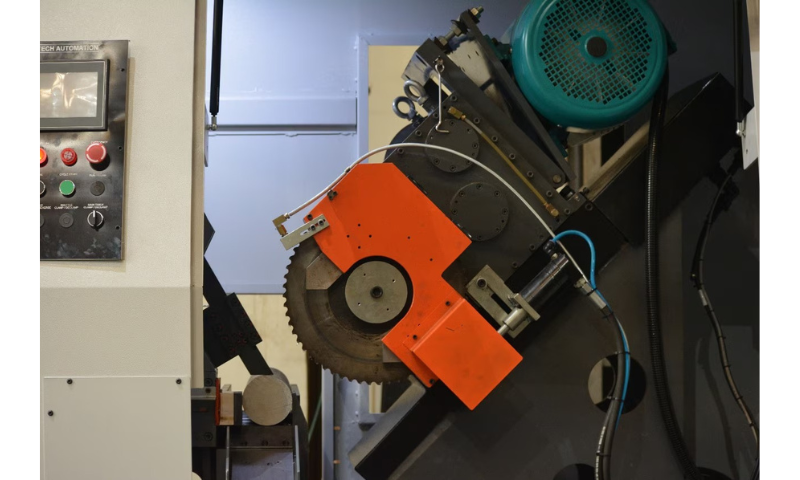

The SANC Series combines the flexibility of semi-automatic operation with the precision of NC controls. Featuring a robust, torsion-free design and heavy-duty gearbox, it is ideal for varied cutting requirements across multiple material profiles.

Machine Construction & Features

Torsion-Free Design

Heavy-duty fabricated structure ensures rigidity and minimizes torsional stress during operation.

Variable Feed Control

Infinitely adjustable cutting feed via ball screw servo motor and VFD for precise speed control.

Dual Mode Operation

Offers both automatic and manual modes for flexible cycle sequence control.

Rapid Head Movement

Cutting head features rapid approach movement driven by servo motor for quick positioning.

PLC Control with HMI

User-friendly touchscreen interface allows for easy operation and monitoring.

Micro-Mist Cooling

Integrated cooling arrangement ensures optimal cutting performance and prevents overheating.

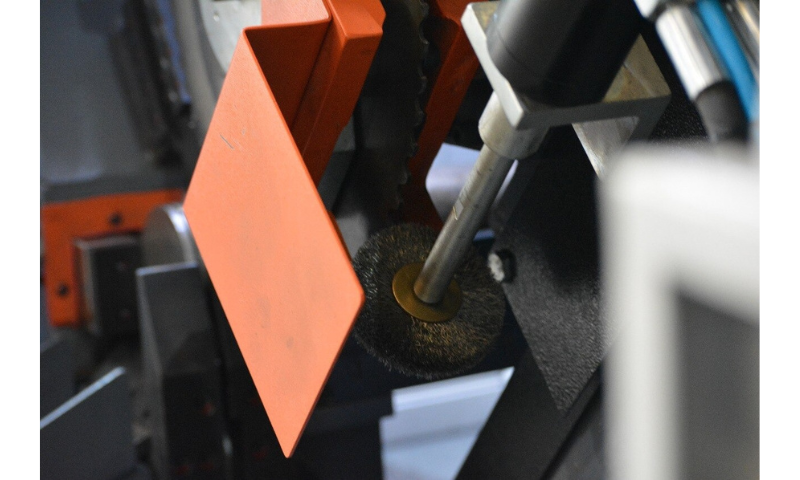

Chip Cleaning System

Includes driver brushes for automatic chip removal from circular blades and a powered chip conveyor.

Auto-Lubrication

Integrated pump ensures proper maintenance of all moving components.

SANC Series Models

We offer a wide range of models tailored to specific cutting capacities:

- Model 60

- Model 80

- Model 100

- Model 125

- Model 150

- Model 220

- Model 250

- Model 275

* Customizable designs available to meet specific operational requirements.

Operational Specifications

| Cutting Head Return | Automatic return to start position after cut |

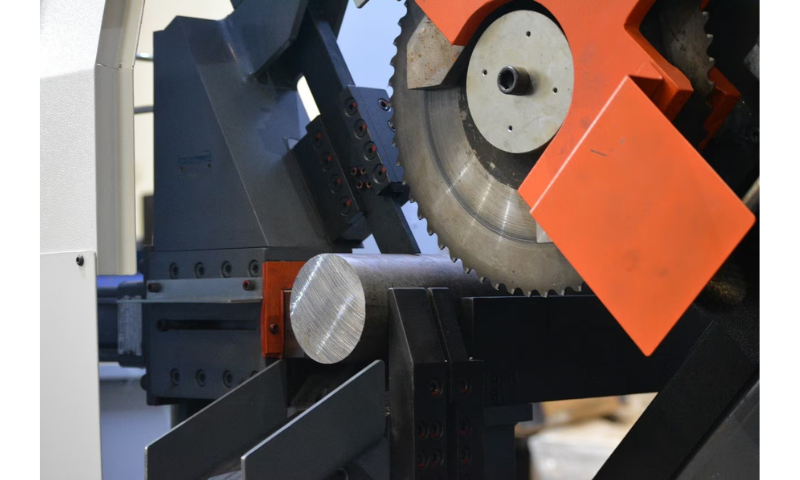

| Job Clamping | Hydraulically operated vice for secure holding |

| Gearbox Type | Heavy-duty reduction gearbox on linear guideways |

| Hydraulic Power Pack | Separate unit with valves, gauges, and oil level indicator |

| Saw Motor Control | Regulated via A.C. frequency drive |

| Saw Stroke | 45º inclined stroke to optimize cutting process |

| Control Panel | High-quality switchgear components for safety |